Katie Compton and Silvie Harder, Policy and Politics editors

When COVID-19 reached Canada in the spring of 2020, the Government of Canada was on track to ban single-use plastics. But in the scramble to reduce the spread of the virus, grocery stores and coffee shops discouraged people from bringing their cloth bags and travel mugs. In addition, the demand surged for personal protective equipment (PPE) like disposable masks and latex gloves. Approximately 129 billion disposable face masks and 65 billion disposable gloves are used worldwide every month.

Plastics are an important and often necessary material for protecting individuals from the transmission of COVID-19. However, the government should not use the pandemic as an excuse to slow down the single-use plastic ban. We need waste reduction policies and initiatives that acknowledge plastics’ vital role in protecting us from infection while reducing their environmental impacts.

The federal government launched Canada’s Plastics Science Agenda (CaPSA) to tackle the plastics problem. The CaPSA supports research to find ways to make plastics more sustainable and eco-friendly. The government wants to achieve zero plastic waste by 2030, and announced on October 7, 2020, that Canada would work towards a ban on single-use plastics.

Bioplastics: The plastic of the future?

Dr. Trevor Charles, a professor in the Department of Biology at the University of Waterloo, explores how bioplastics could help us create single-use plastics that won’t live on in our landfills or water systems indefinitely. Charles, who is also the Director of the Waterloo Centre for Microbial Research and the Chief Science Officer and Co-Founder of Metagenom Bio Life Science Inc., studies bacteria that convert biomatter into raw materials for bioplastics.

The term bioplastic refers to several categories of plastic, and Charles emphasizes that it’s important to understand what a manufacturer means when they use this label.

“You can have plastics that come from a biological source, but are not biodegradable,” he says “We can also have plastics that come from a fossil fuel source but are biodegradable. And then you have [plastics] that are both from a biological source and are biodegradable.”

Charles focuses on the third category – biodegradable plastics made from biological waste, such as food waste. Creating processed foods generates large quantities of by-products like starch and lactose, and many of these by-products end up in landfills. But there are strains of bacteria that naturally convert these waste products into polymers called polyhydroxyalkanoates (PHAs), which are an alternative to fossil fuel-based plastic polymers.

“We’ve figured out how to engineer the bacterial cells so that they could efficiently use waste lactose, and then convert that to the bioplastic,” he says.

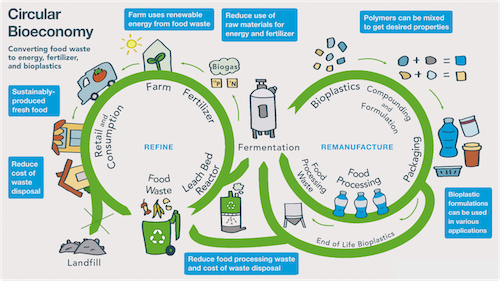

Restaurants, grocery stores, and individual consumers are also significant sources of food waste. However, turning compost into bioplastic is more complicated than feeding lactose to bacteria. Dr. Charles and his collaborators are working on creating circular bioeconomy solutions. These systems would not only convert food waste into bioplastics in an economically-competitive manner, but also help grow more food.

How bioplastics are made

To make bioplastics in a circular bioeconomy, you start by spreading biowaste onto a grid in a bioreactor. As the biowaste decomposes, it creates leachate (liquid). If you continue to recirculate this liquid over the remaining biowaste in the system, you get volatile fatty acids (VFAs), which you can use to create PHAs. “The bacteria love these VFAs and are really good at converting them into bioplastic,” Charles says.

As this bioreactor churns, it will also produce water, nitrogen, phosphorus, and biogases such as CO2 and methane.

“That’s a perfect combination of material that you could use to produce more food,” Charles says. He and his team envision a modular hydroponic system that takes in food waste and generates PHAs for food packaging, water and fertilizer for growing new crops, and methane to power the entire system.

An example of how food waste flows through a circular bioeconomy. Image by Rebecca Co, Metagenom Bio.

Obstacles to producing bioplastics

The potential market for bioplastics goes beyond food packaging. Charles points out that plastic is an important component of many products.

“In paints, for example, you have a lot of plastic polymers,” he says. He also sees bioplastics playing a role in more environmentally friendly PPE.

But there are obstacles – both in terms of manufacturing capacity and government regulation – to producing and marketing bioplastics on a meaningful scale. “Right now, only a very few [PHAs] have been used and are commercially relevant.”

The key challenge, says Charles, is identifying the properties of the plastic you need and figuring out how to generate a bioplastic with those properties.

“Say you want something to replace the stretchy rubber band for a facemask. Somebody has to look at all of the materials that are available and see if [a bioplastic] could replace that,” he says.

He also thinks that more clarity around bioplastic regulation is necessary before Canada can build a viable bioplastics industry. “There’s still uncertainty about how bioplastics will be regulated. So, whether they will be captured within the overall ban of single-use plastics, or whether they will be seen, in a regulatory sense, as a solution.”

Despite these obstacles and challenges, Charles is optimistic that bioplastics have tremendous promise for making the plastics in our lives – whether they are protecting us from infection or helping keep our food fresh – more sustainable.

~

Quotes have been edited for clarity.

Feature image: Discarded masks on the streets of a Montreal neighbourhood. Photos by Silvie Harder